Rigid Flex Circuit Boards for Flexible Touch

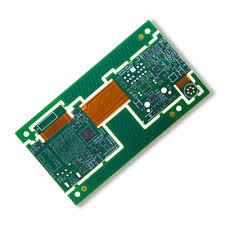

When designing a new electronic device, the engineer must take into account both the device’s mechanical and electrical requirements. Rigid-flex circuit boards are one option that can fulfill both requirements at a lower cost than other wired solutions. They can also save space in the final product by replacing multiple rigid circuits, connectors, and wire harnesses with a single, integrated circuit board. However, there are some challenges that must be addressed to successfully design a rigid flex circuit board.

A key challenge is integrating the flexible components of the circuit board with its rigid sections. This can be done by using stiffeners encapsulated in the coverlay or with thermally-cured acrylic adhesives. Other options include incorporating anchors and spurs into the structure of the PCB to reduce stress and prevent failure. Achieving this requires proper collaboration between designers, fabricators, and assemblers during the design process to avoid errors that may occur in production.

Other rigid flex circuit design challenges include minimizing the size of the flex circuit while maintaining adequate signal integrity. This can be accomplished by reducing the amount of copper in the flex area, using narrower circuit traces, and by increasing the thickness of the rigid portions of the circuit board.

Rigid Flex Circuit Boards for Flexible Touch Controls

Another challenge is ensuring that the flex circuits can withstand the mechanical stress of bending and other dynamic applications. This can be achieved by limiting the amount of conductors in the flex area, increasing the thickness of the rigid portion, and designing for a minimum of 100 million cycles of use. It is also important to consider environmental factors such as temperature, humidity, and vibration, which could impact the lifespan of a rigid flex circuit board.

Rigid flex circuit boards are available in many different configurations. They can be single-sided, double-sided, or multi-layer. Single-sided flex circuits have only one conductor layer, while double-sided and multi-layer flex circuits have two or more conductor layers. They can be fabricated with or without plated through holes, though plated through hole versions are more common. They can also be produced with or without protective coverlayers on one, both, or neither side of the completed circuit.

When selecting a turnkey PCB manufacturer, it is important to choose a company with the right expertise and experience to ensure that your project meets all of your expectations. You should also make sure that the company is certified and registered to manufacture, assemble, and test all of its products. It is best to visit the manufacturer’s facility and ask questions about their manufacturing capabilities before you select a supplier.

Rigid-flex circuit boards can be used in a wide variety of electronic devices, including mobile phones, laptops, digital cameras, tablets, and handhelds. They can be designed for static or dynamic applications, where the flex area is required to bend only during installation in the final product (static application), or where the flex circuit will be repeatedly flexed throughout the life of the product (dynamic application). Rigid-flex circuit boards have advantages over other interconnect systems, such as contact crimps, solder joints, and connectors, by reducing the number of points of interconnection within the final assembly.